The BAR BOX

- Category: product design

- Client: Samantha Piperhoff

- Project date: March-May, 2022

Group Project

This is one of my group project of year2 semester2. Rodothea who is a designer made branding design and I made 3D prduct Design. There are other 2 group which do same project. Specifically, We focus on the client feedback and designy and useful design. The target is Eco aware user that want to cut down on single use plastics.

Work

Travel Soap

This product is travel soap conttsiners. so it ia designed portable and useful for the travel.

Designer Work

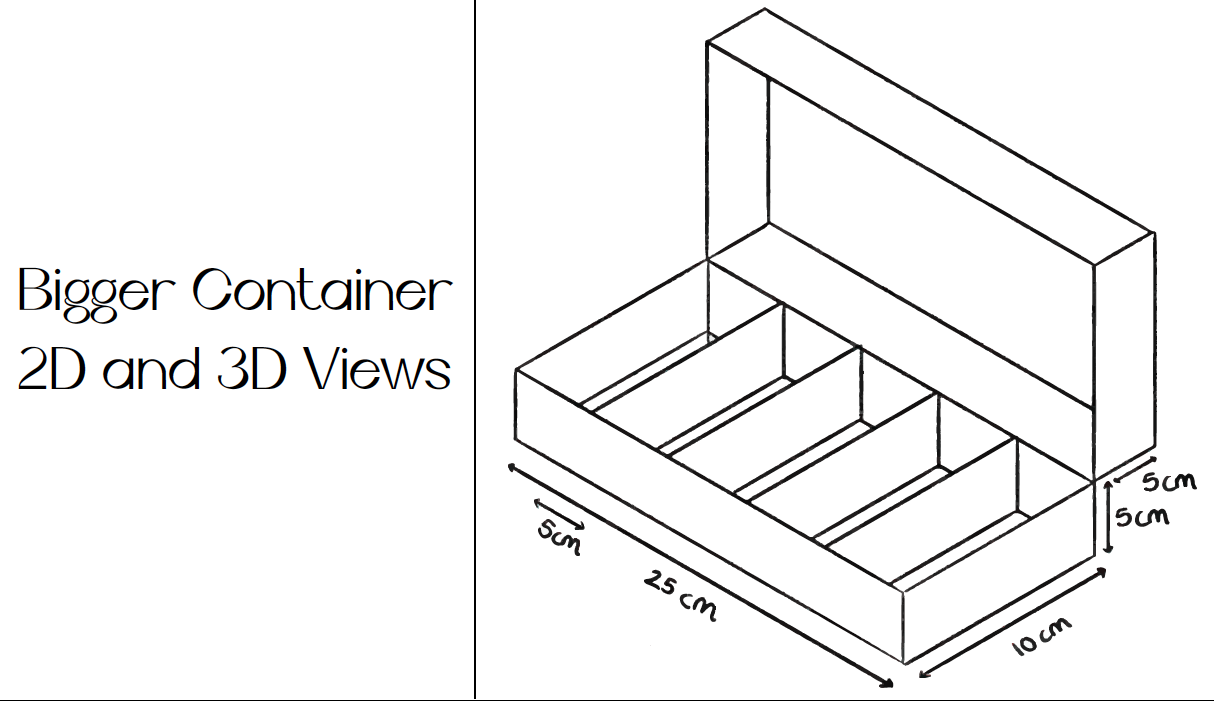

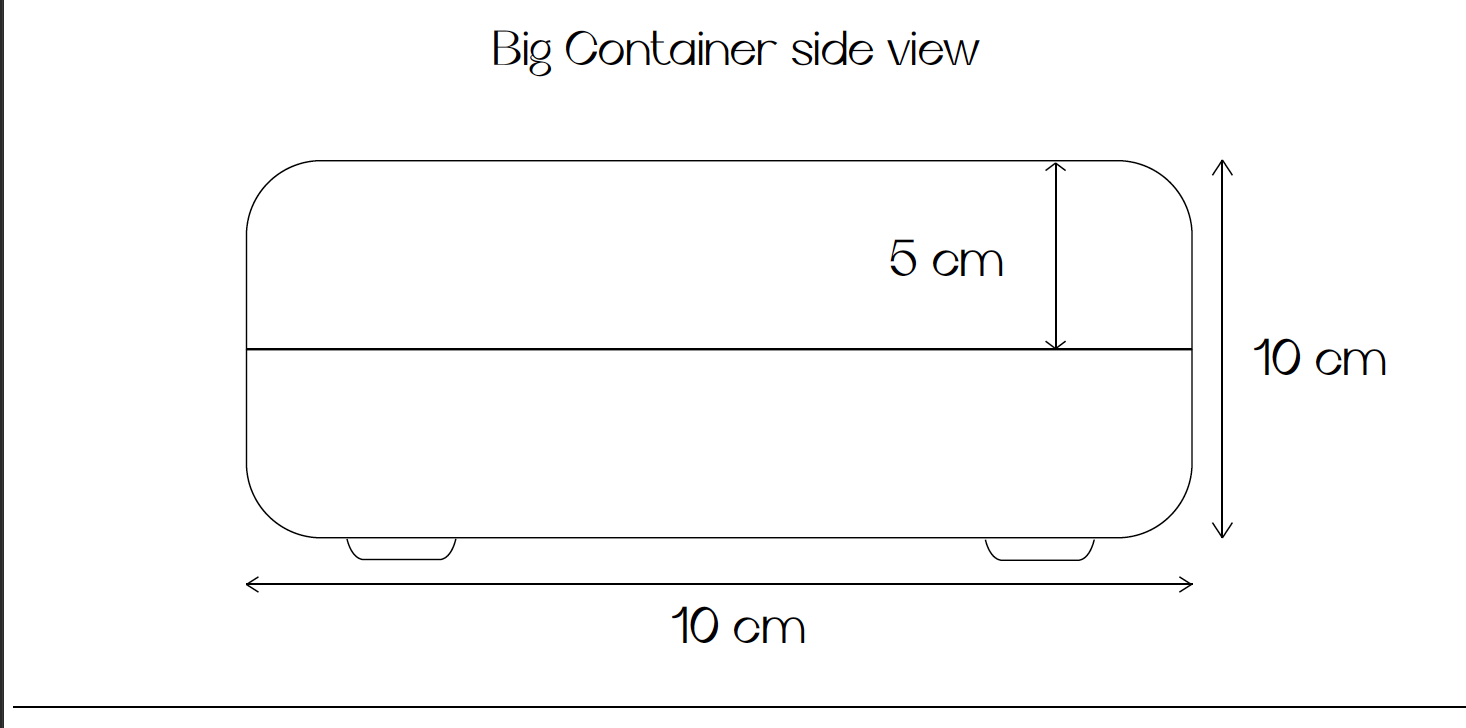

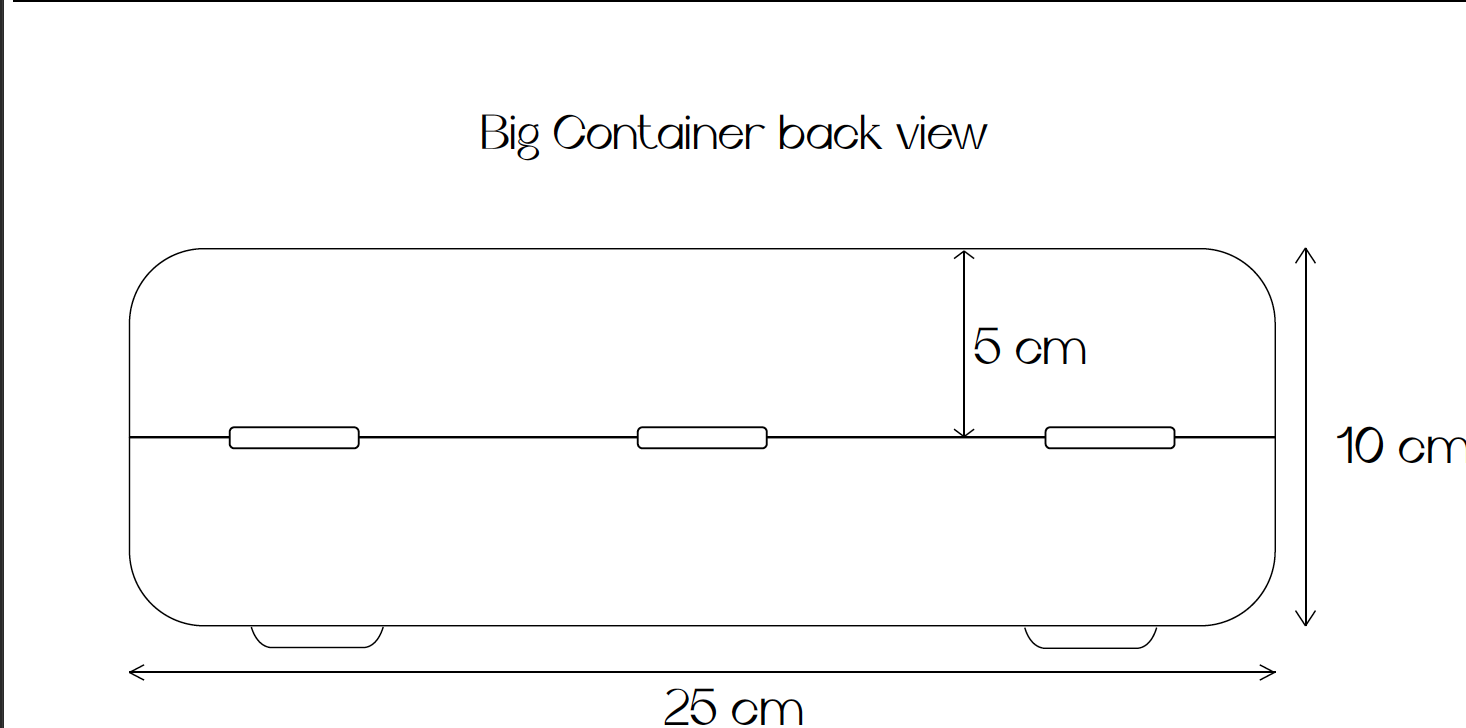

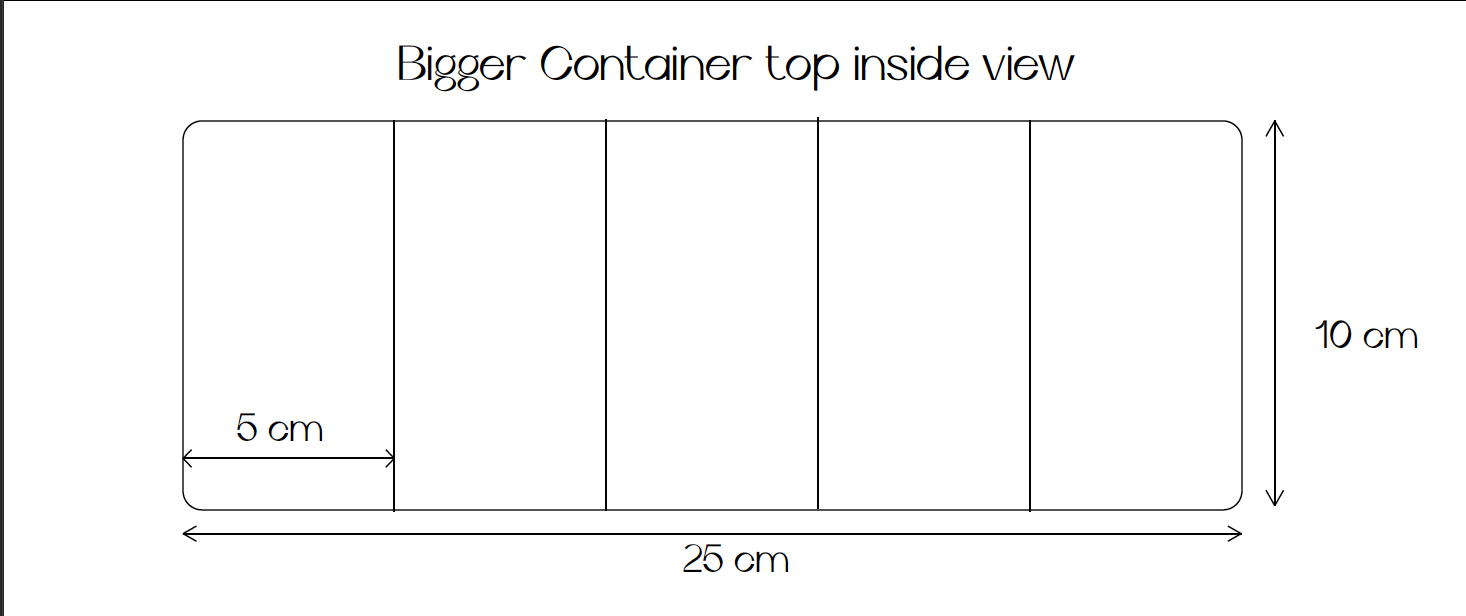

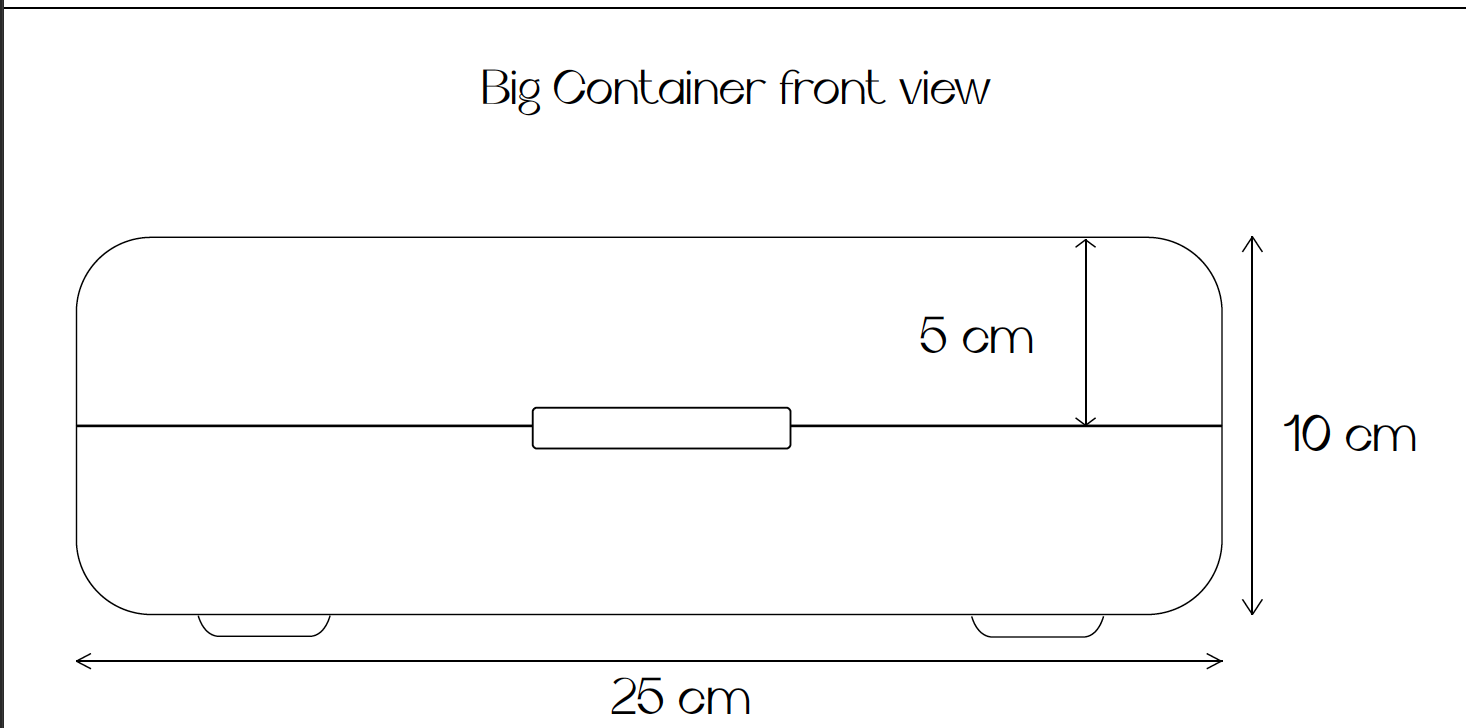

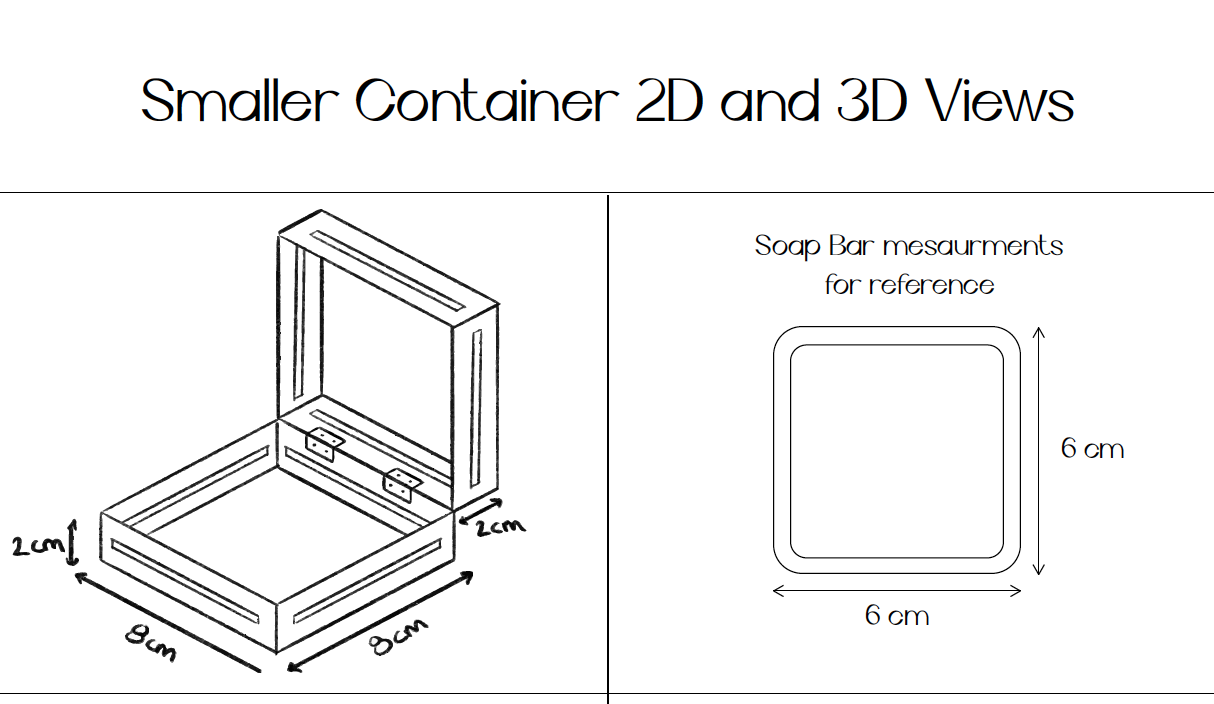

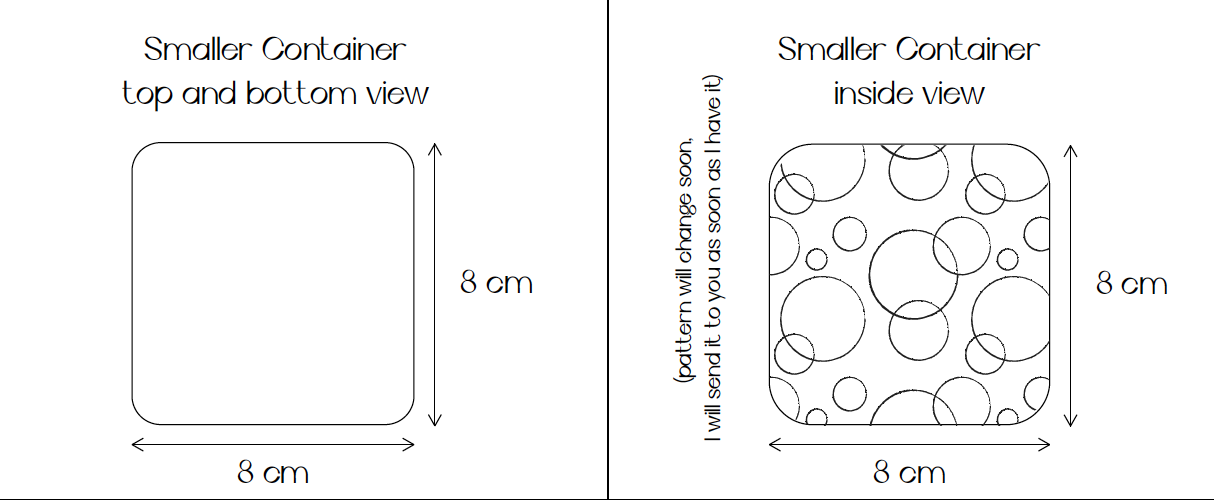

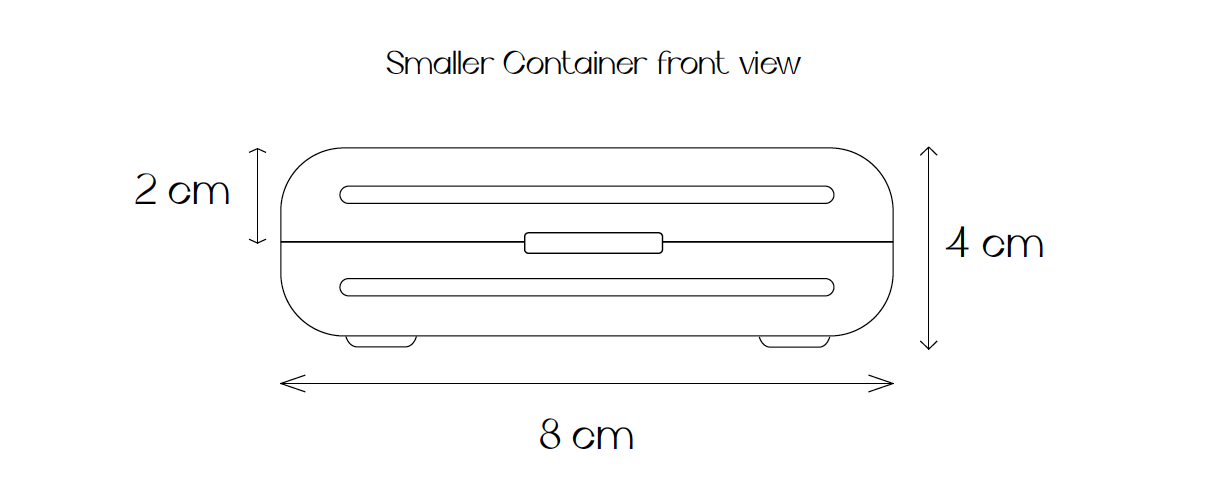

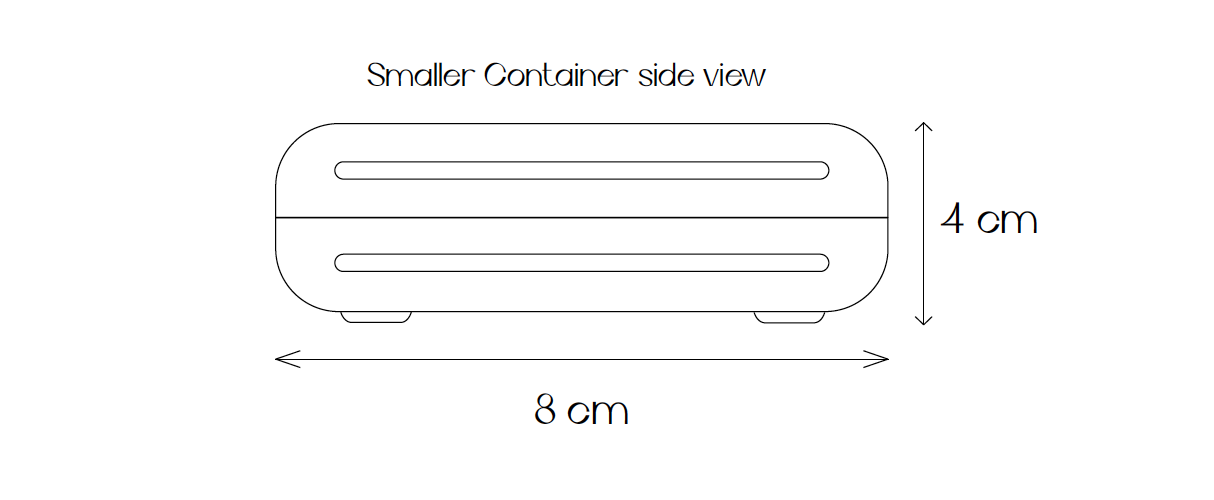

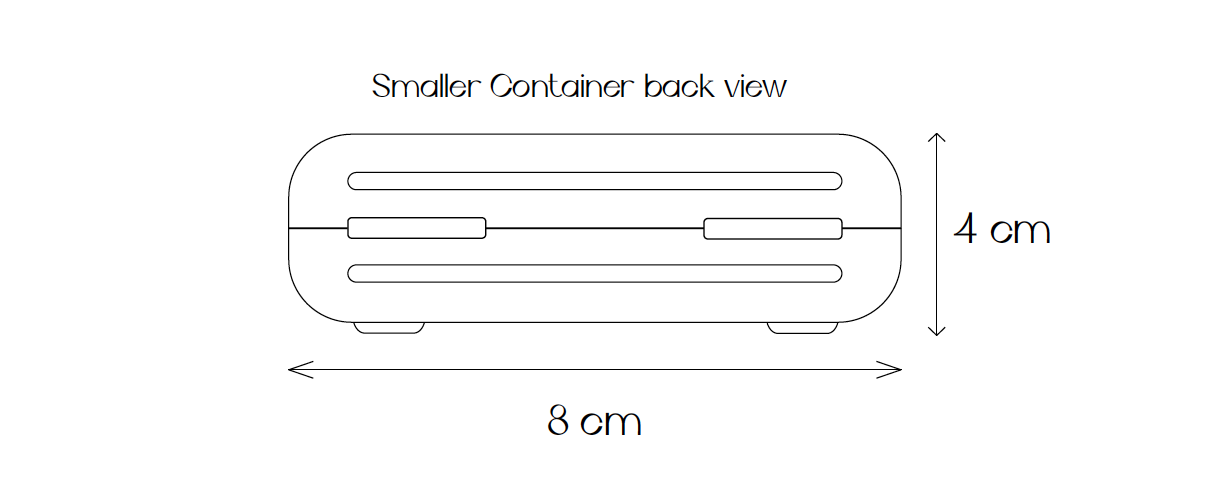

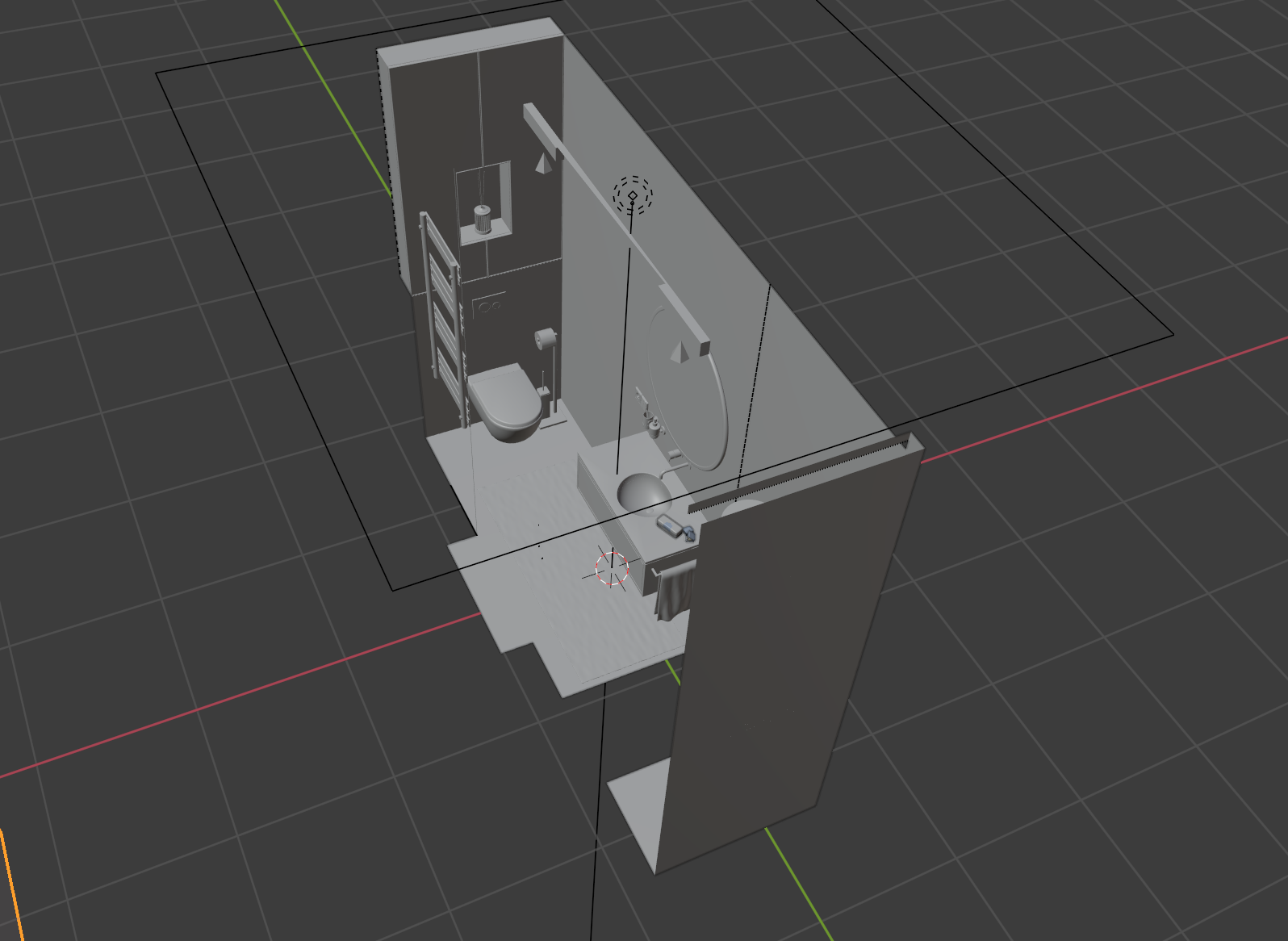

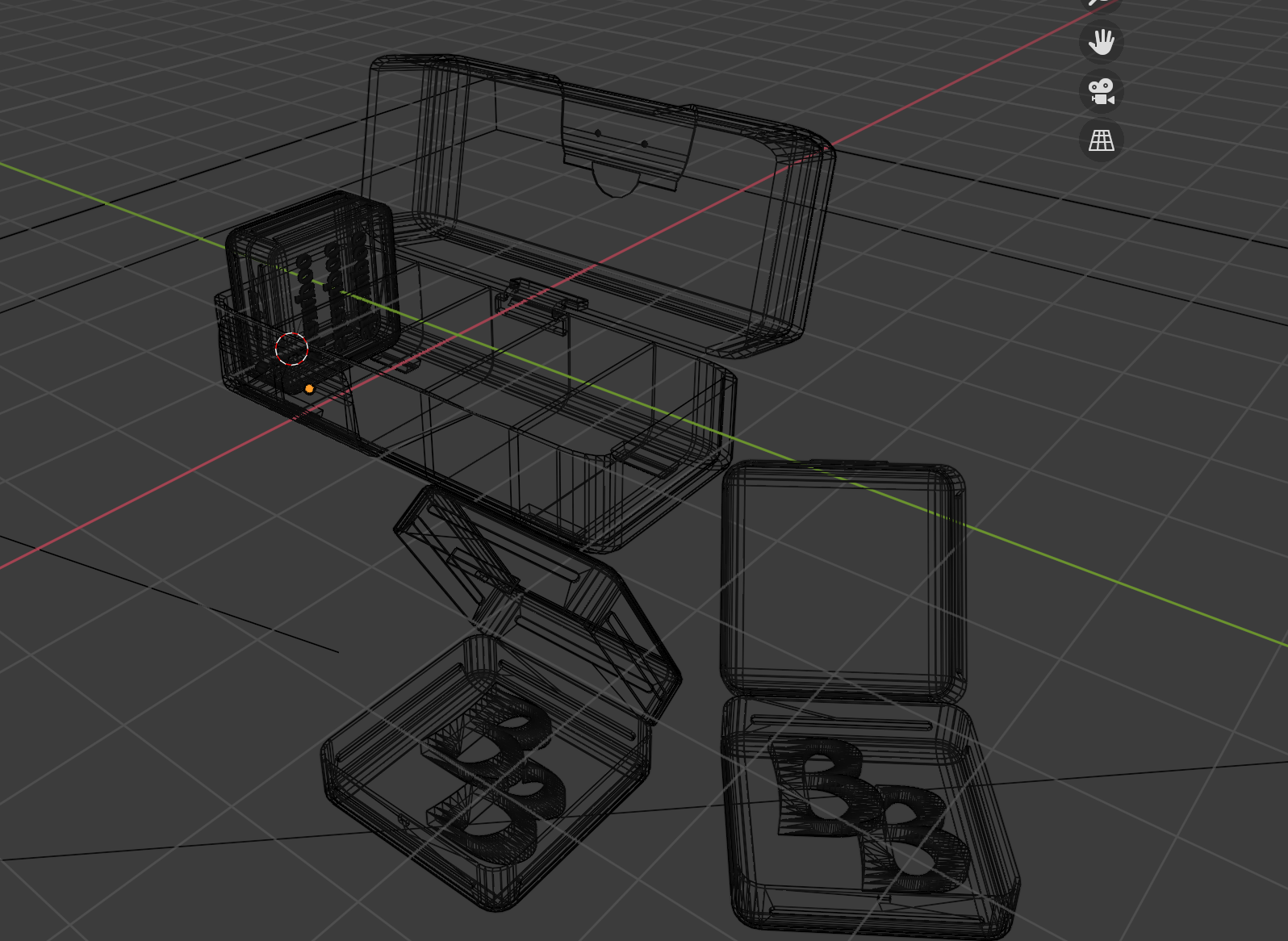

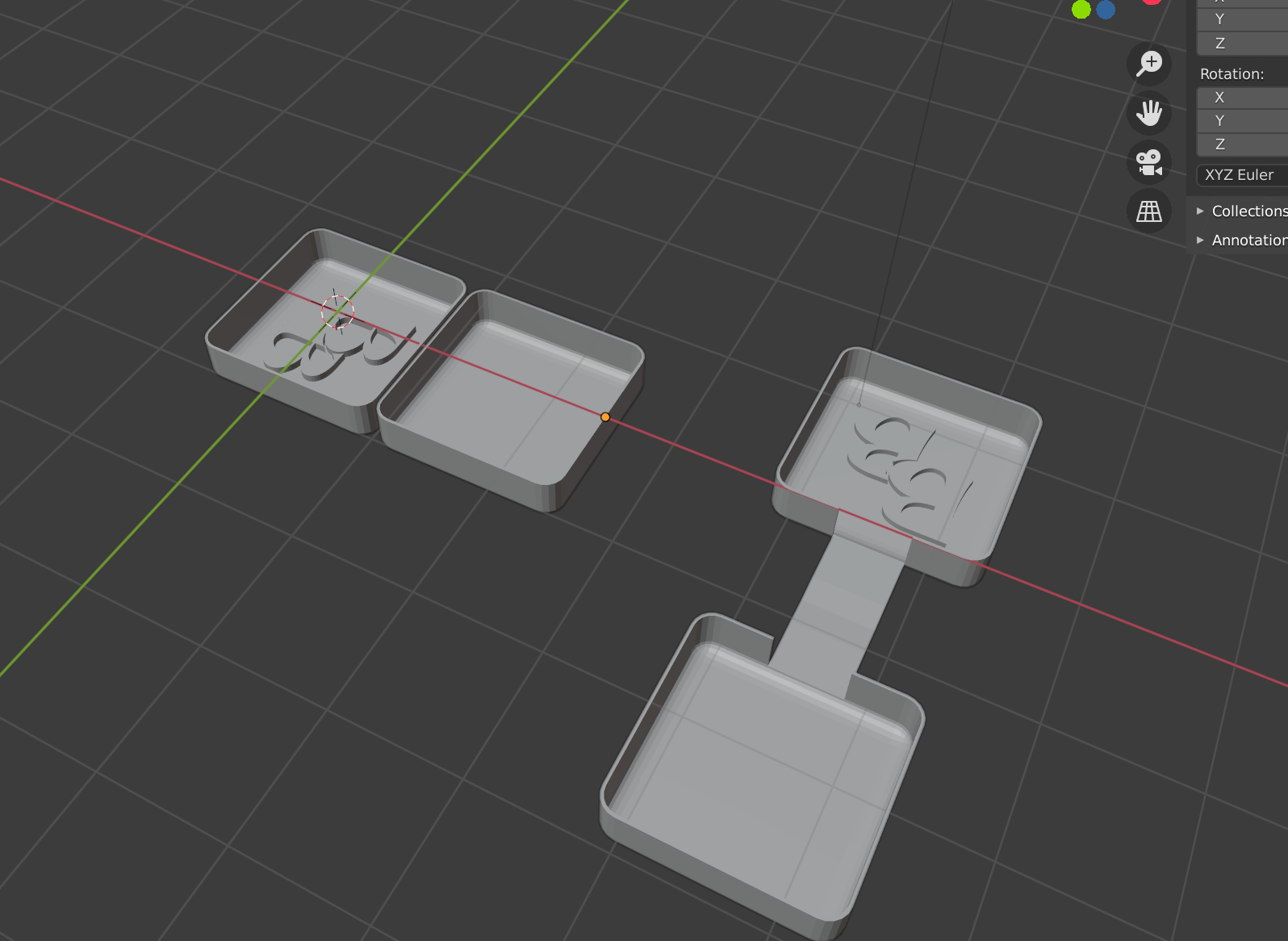

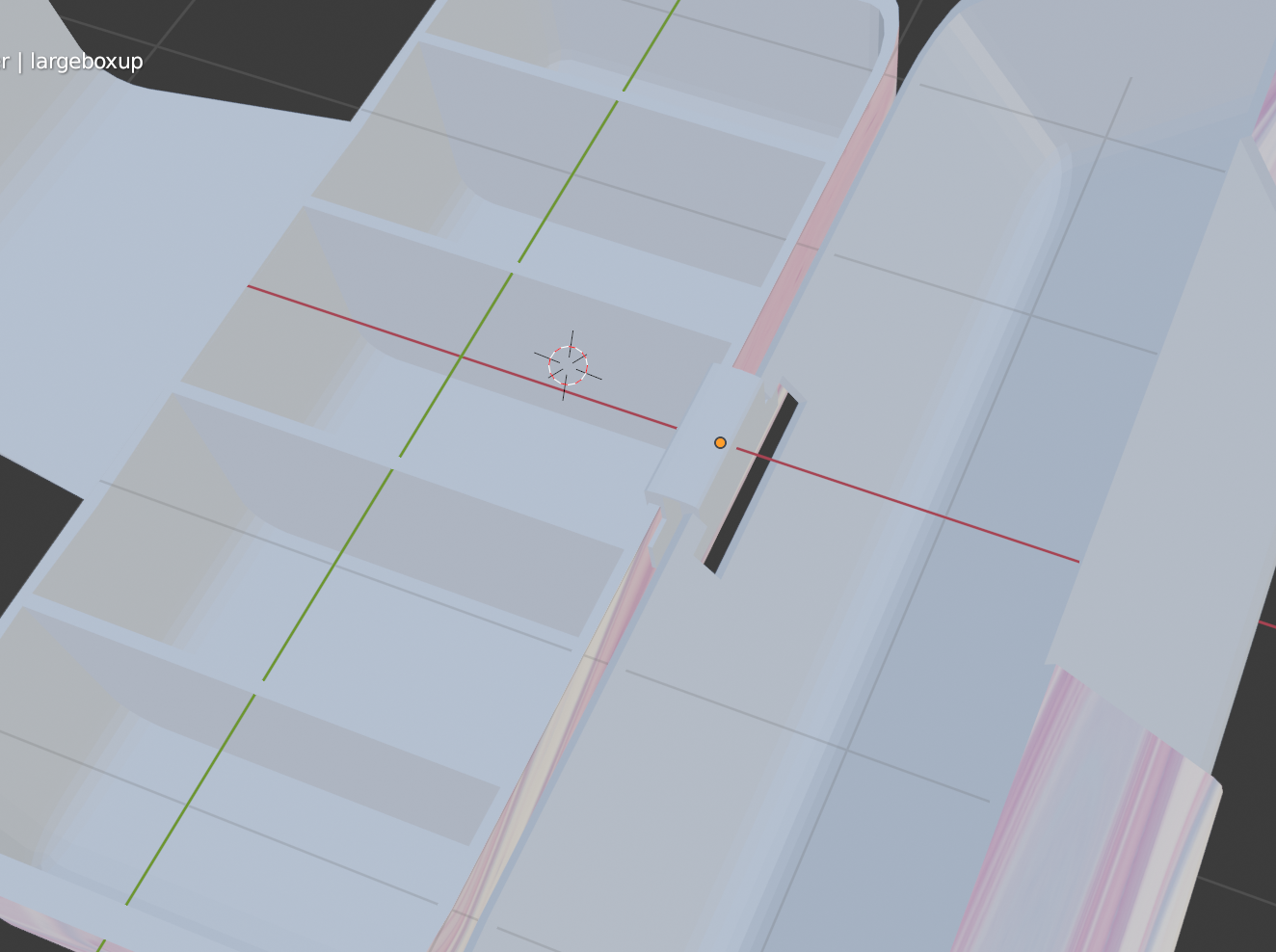

We have created a product to suit soap bars of approx. 6 cm square shape. This is an initial sketch. We started modelling with a blender based on this dimension.This design has five small soap boxes in one large box, designed to easily carry small amounts of soap with different contents.

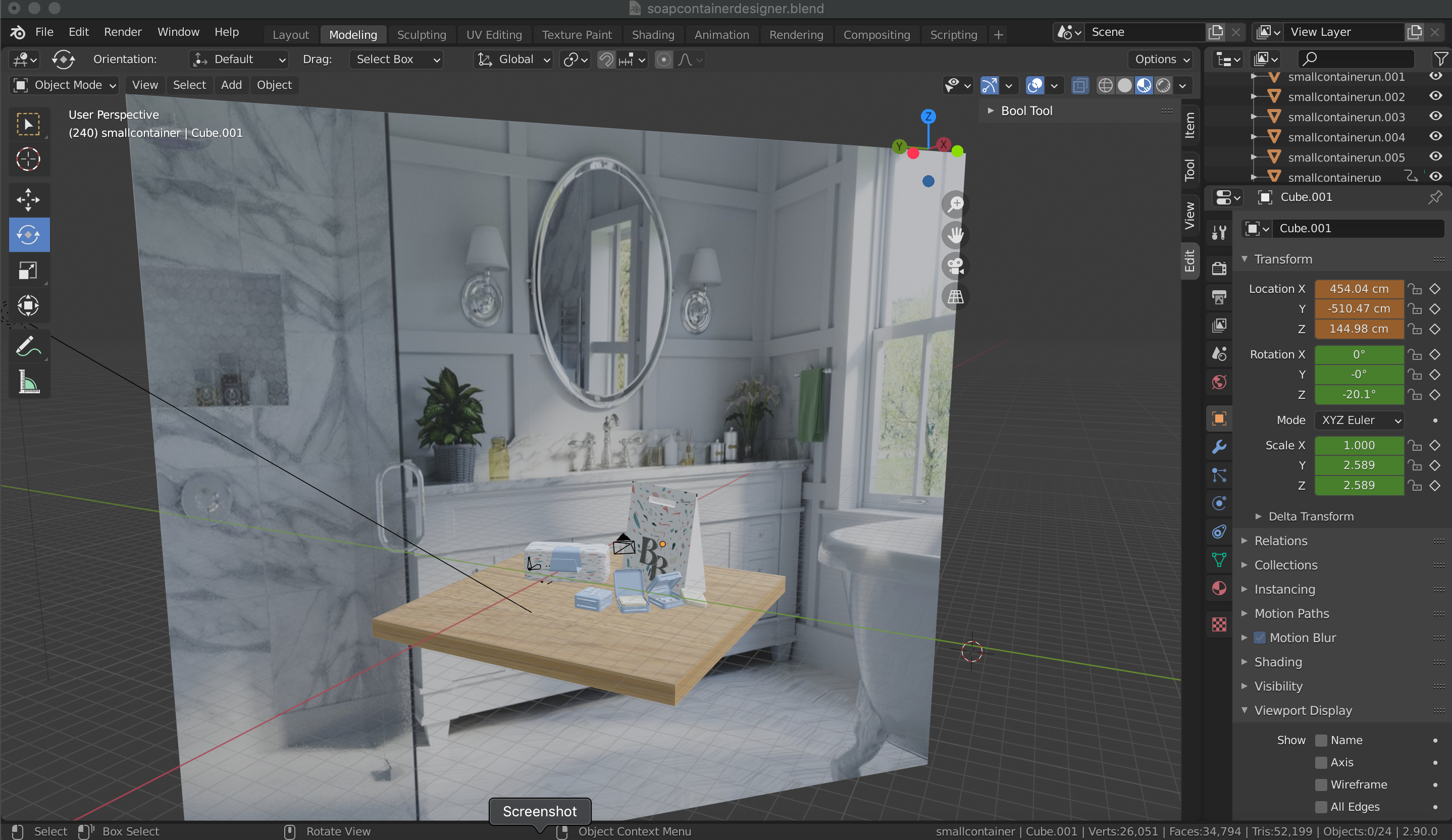

Initial Design Work

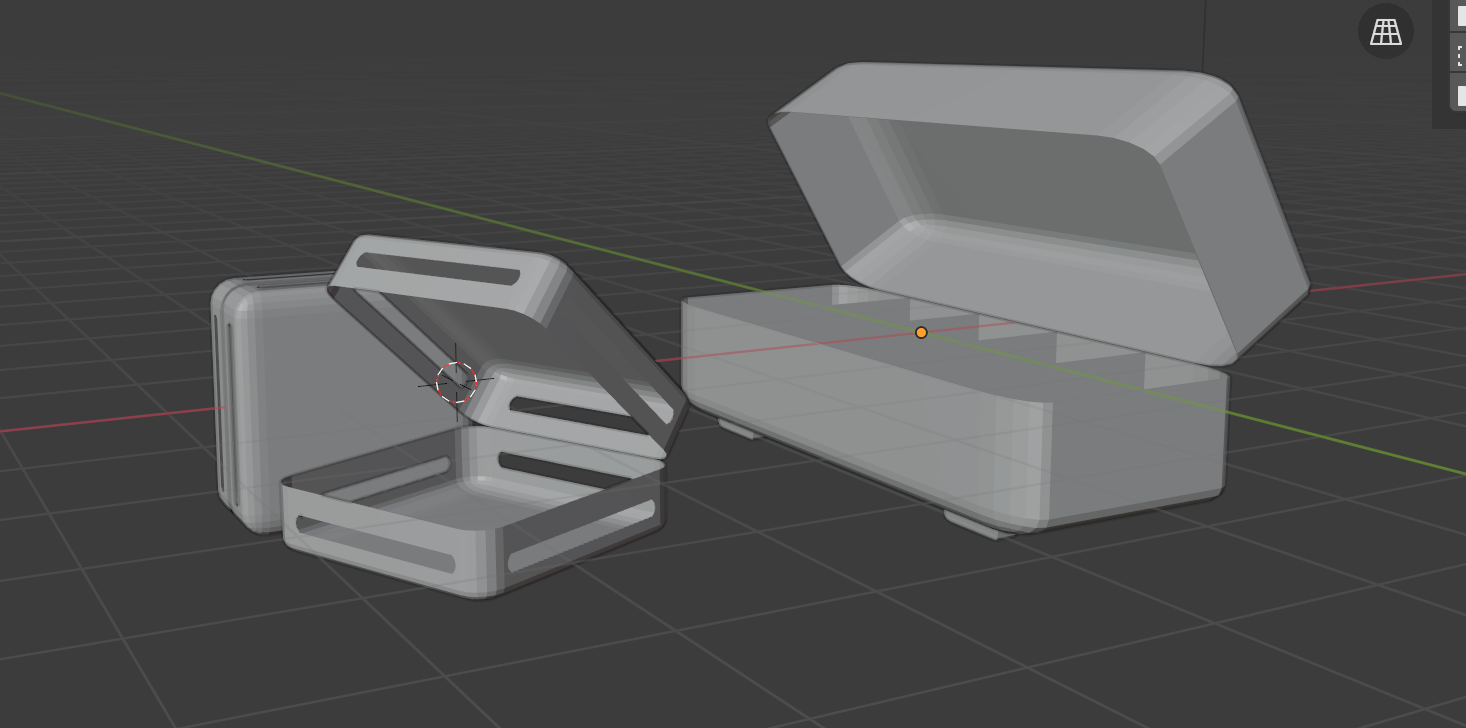

I do modelling of intial product design for mock up. I was conscious of the dimensions of the soap to make it easy to takeI discussed with the designers and added ideas such as holes to release moisture and clip parts to make it look pretty. We also revised this product design three times to bring it closer to the final design. Also I made bathroom envirnment for mock up rendering.

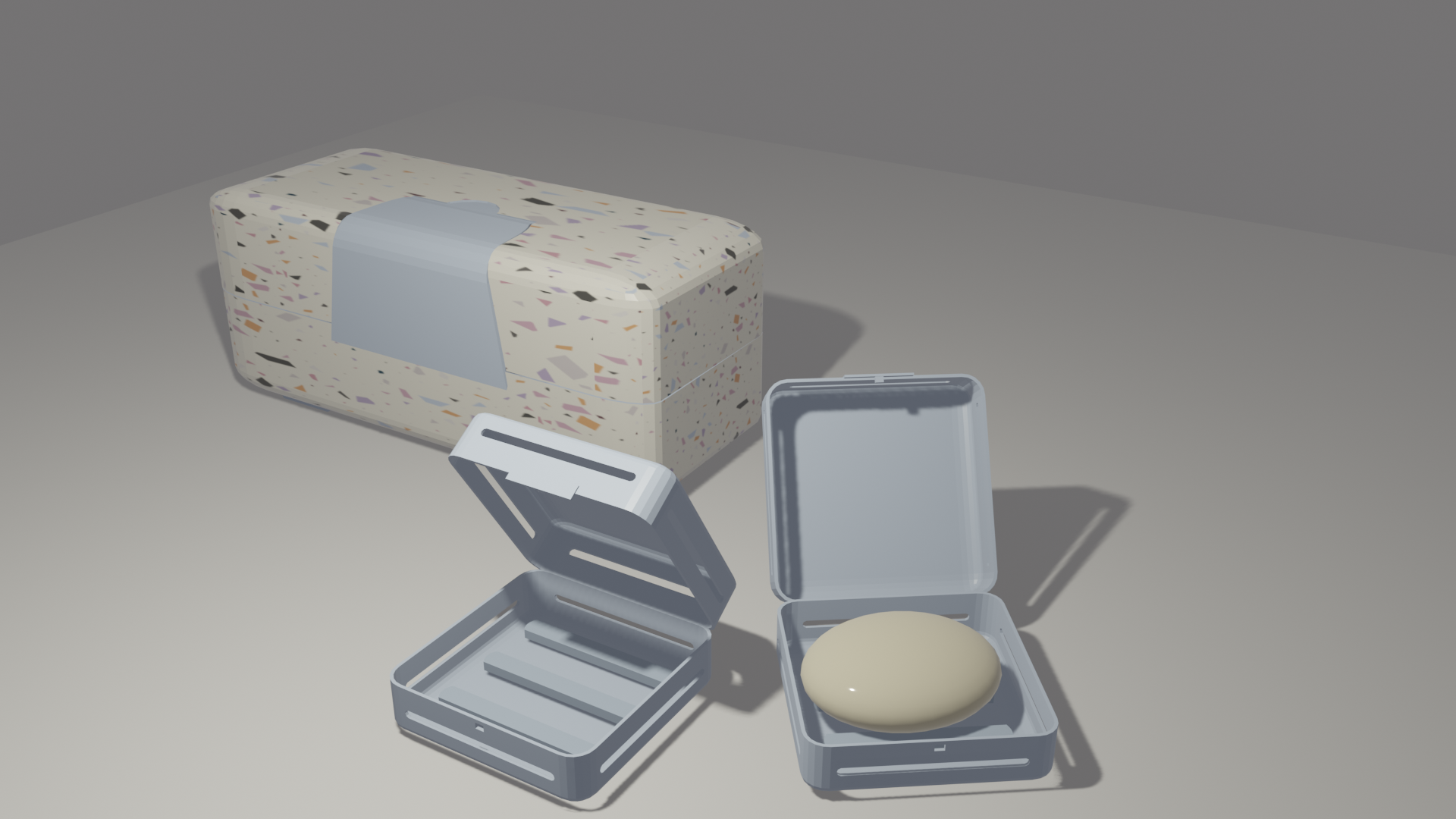

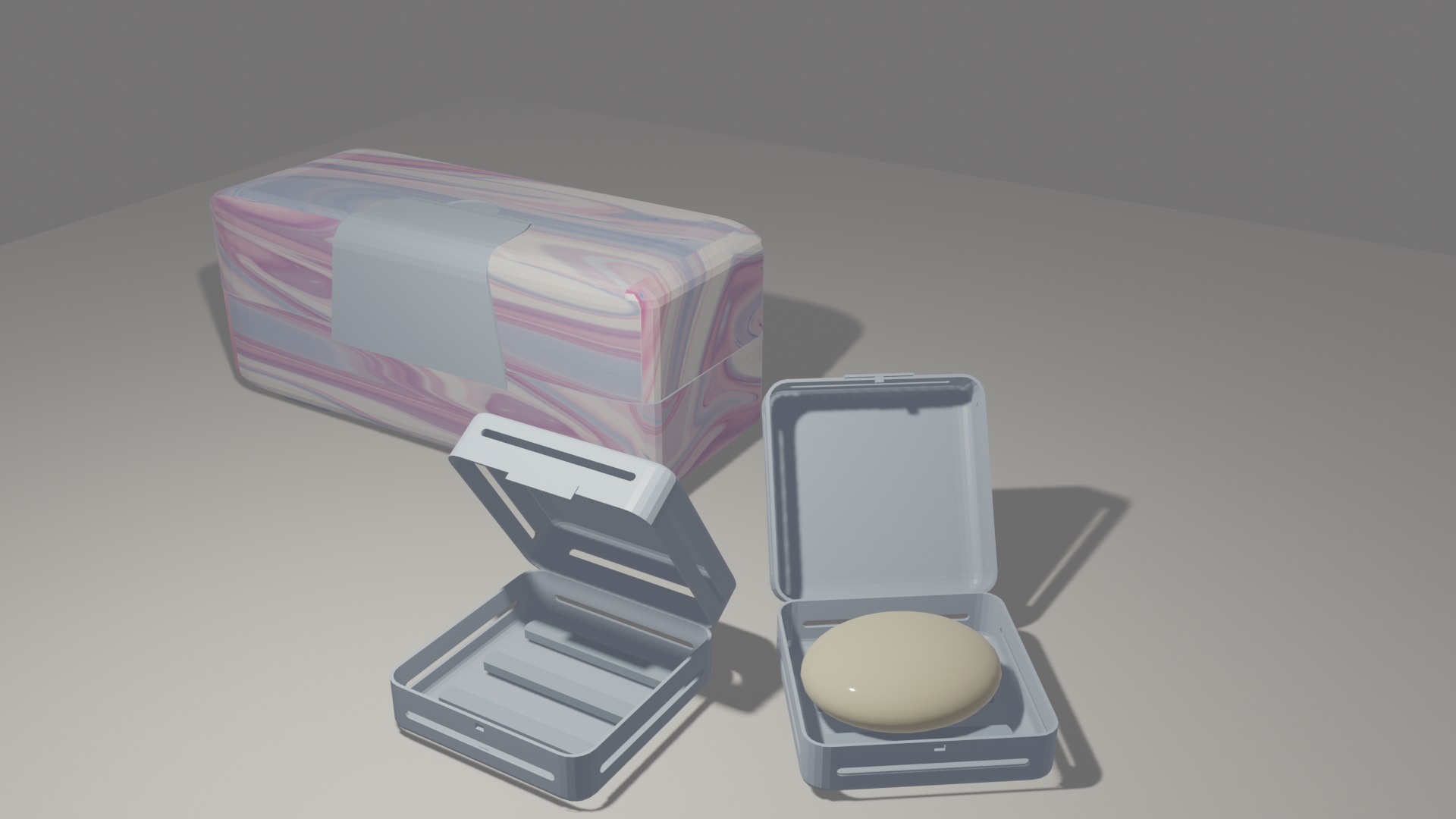

Initial Rendering

3D Design

Based on feedback from initial design clients and designers, some modifications were made.

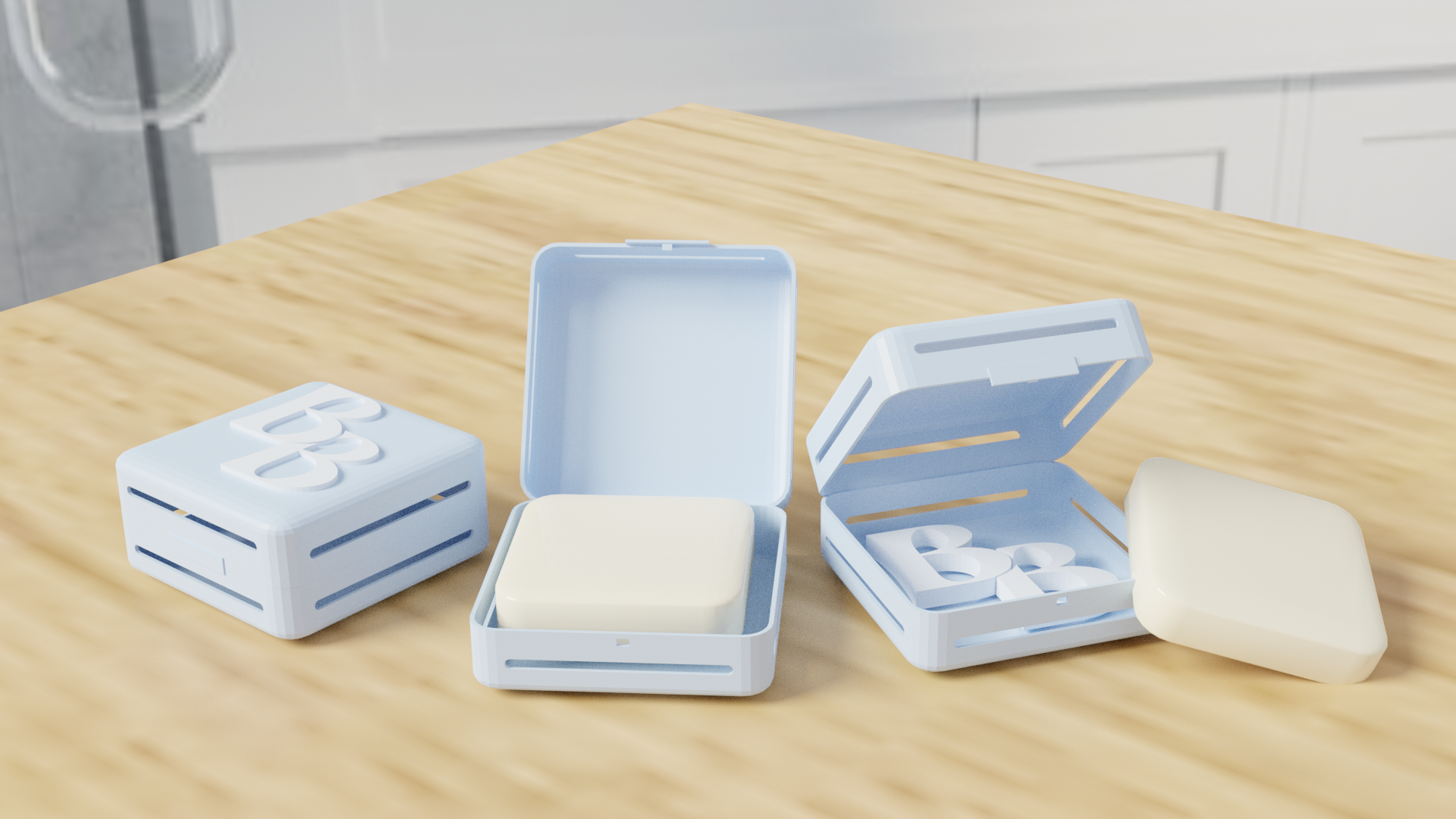

Final Rendering Design

The final renderings were bright and clear. Focused renderings were also done for both large containers and small boxes. To show the branding, the logo was made larger than actual size and bags were placed.

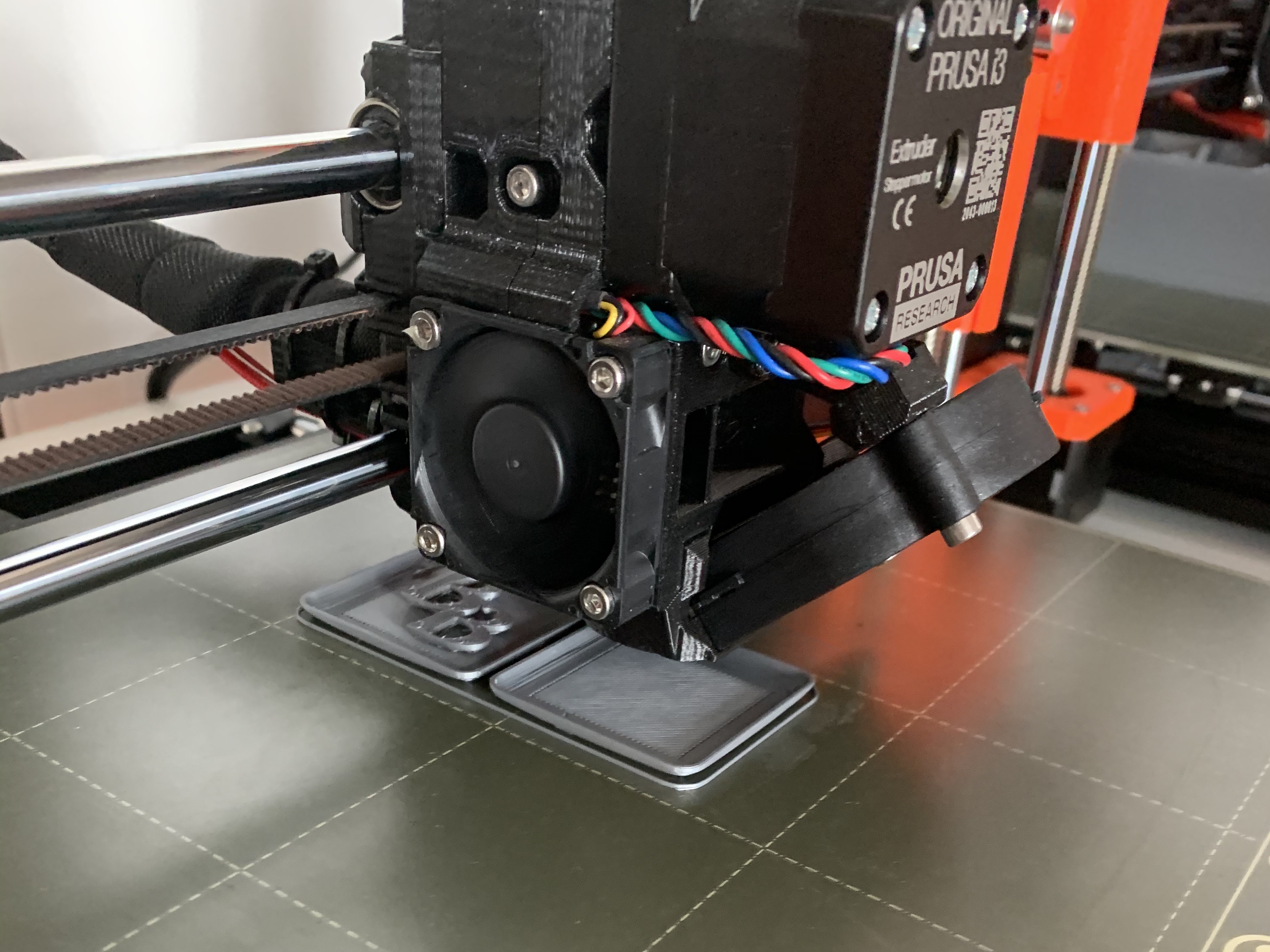

3D printing

This is the first 3D print of my design. It was the most difficult and caused some problems.

We are printing from a small box at scale and discussing how it should be created. We are now planning to do the final 3D prints as close to actual size as possible during the Transmedia exhibition as an opportunity for the client to see the 3D prints as well.

Still working process....

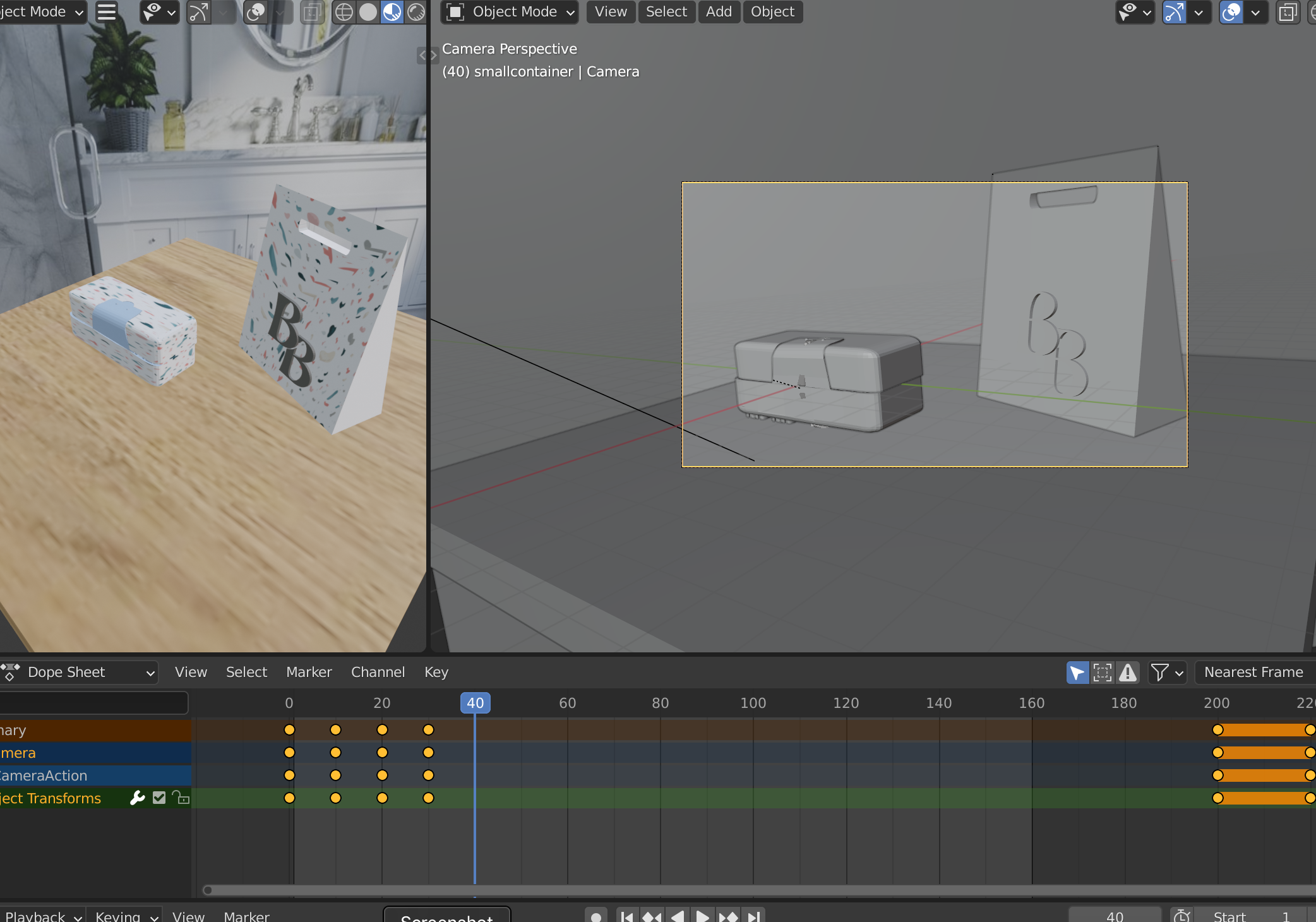

Animation

The animation lasts approximately 7 seconds and consists of removing a box from a bag, opening a large box, removing a small box, opening a small box, removing soap. As there are few designs for the joints of the boxes that can be made with a 3D printer, an animated rendering was done with the ideal design.